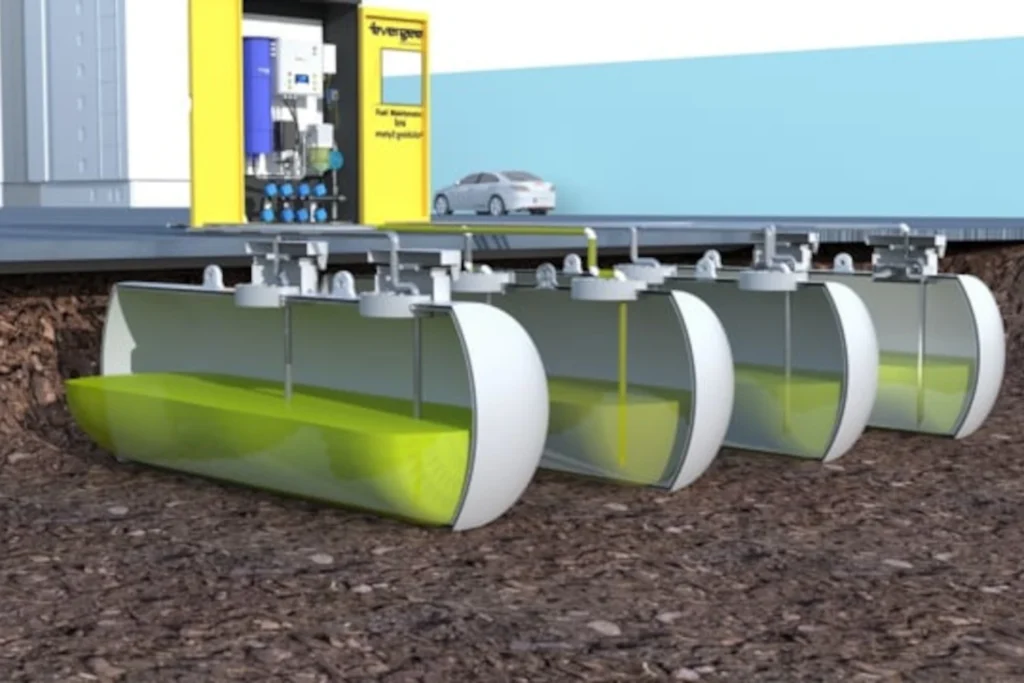

Introduction to Fuel Polishing Systems: Applications and Industrial Uses

Fuel polishing systems play a crucial role in maintaining the quality and integrity of fuel used in various industrial applications. These systems are designed to remove contaminants, water, and other impurities from fuel, ensuring optimal performance and reliability of equipment and machinery. Let’s delve into the applications and industrial sectors where fuel polishing systems are commonly employed.

Marine Industry

Fuel polishing systems are extensively used in the marine industry to maintain the quality of diesel fuel stored onboard ships and vessels. Clean fuel is essential for the efficient operation of marine engines, preventing issues such as clogging of filters, injector fouling, and engine downtime.

Power Generation

Power generation facilities rely on fuel polishing systems to ensure the uninterrupted operation of backup generators and diesel engines. Clean fuel is essential for backup power systems in hospitals, data centers, and critical infrastructure, where reliability is paramount.

Manufacturing and Industrial Facilities

Manufacturing plants and industrial facilities often use diesel generators and backup power systems to ensure continuous operations. Fuel polishing systems are employed to maintain the quality of stored fuel, minimizing the risk of equipment failures and production downtime.

Construction and Mining

Construction sites and mining operations often utilize diesel-powered equipment such as generators, excavators, and trucks. Fuel polishing systems help to keep the diesel fuel clean, preventing equipment failures and minimizing maintenance costs in these demanding environments.

Transportation and Logistics

Fuel polishing systems are employed in fuel depots, trucking companies, and logistics centers to ensure the quality of diesel fuel used in fleets of trucks, buses, and other vehicles. Clean fuel improves fuel efficiency and reduces emissions, contributing to cost savings and environmental sustainability.

Agriculture

Farms and agricultural operations rely on diesel-powered machinery for various tasks, including tractors, harvesters, and irrigation pumps. Fuel polishing systems help to maintain the performance and longevity of agricultural equipment by removing contaminants and water from stored diesel fuel.

In conclusion, fuel polishing systems are indispensable in various industrial sectors where the reliability and performance of diesel fuel-powered equipment are critical. By removing contaminants and water from fuel storage tanks, these systems help to ensure the efficient operation of engines and machinery, contributing to enhanced reliability, reduced maintenance costs, and improved environmental sustainability.

COMPANY PROFILE

EVERGEE is based in Istanbul and actively serves Eastern Europe, Africa, Middle East, Gulf, Russia and CIS Countries. We provide engineering and supply services for energy infrastructures.

Evergee is also specialized in Critical Facilities Engineering and Business Continuity Services. Diesel Fuel Continuous Maintenance and Diesel Fuel Polishing Systems are one of the critical services given to intolerant sectors to unexpected shutdowns such as Data Centers, Banking Sector, GSM Operators, Military Bases, Mining Industry, Hospitals and all other vital facilities where downtime costs much.

VISION AND MISSION

EVERGEE has a concrete solution and satisfaction-oriented vision that serves its customers with the most up-to-date technologies. It works continuously to become a global power in the field of Energy Facilities and Engineering and always keeps “People” in the centre of its services.

EVERGEE works with the mission of “Human-Centered Engineering” that we call “HUMANEERING”. We continually develop ourselves to be a global power, and we present the most advanced technologies to our customers and never compromises from the concerns of efficiency and continuity.